Check out some of our work

On this page we’ll show some of our past work. Here you can find bigger and smaller projects from the past decade or so. There are some DC/DC action aswell as AC/DC.

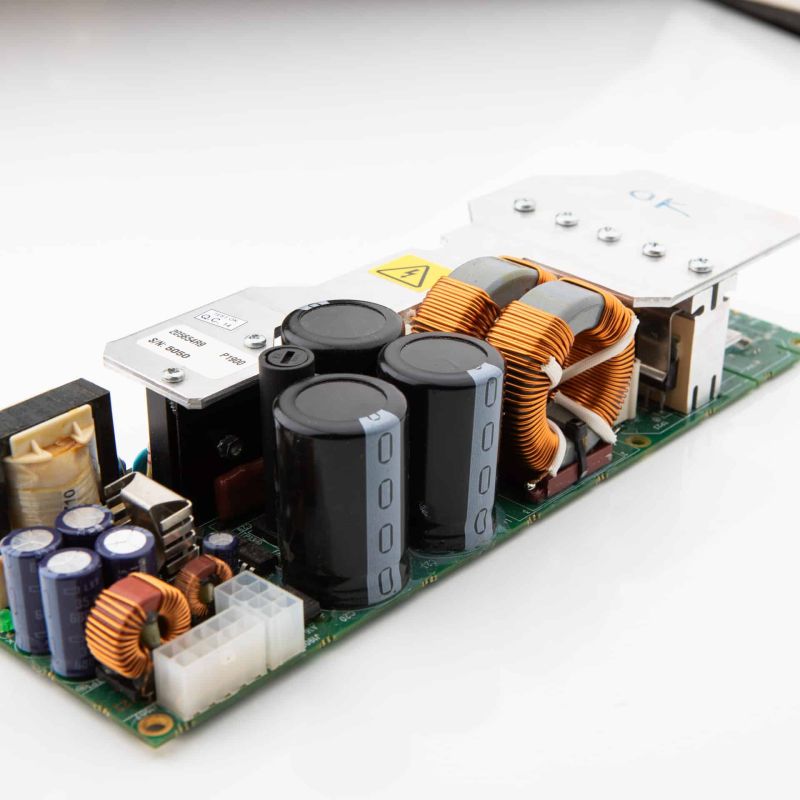

Industrial power supply family

UL certified power supply family 60W to 1kW 1-phase and 3-phase

Our biggest project to date was development project for German company Balluff GmbH. We developed full product family of 24V IP20 and IP67 industrial power supplies for global market. Excello was responsible for developing all of the power electronics, designing mechanics and look of the devices and also software development.

In this project we also developed unique predictive maintenance algorithim to predict aging of the power supply based on electrolytic capacitor degration.

This was the first power supply family in the world to integrate device with IO-LINK bus system. Other competitors has since followed our lead.

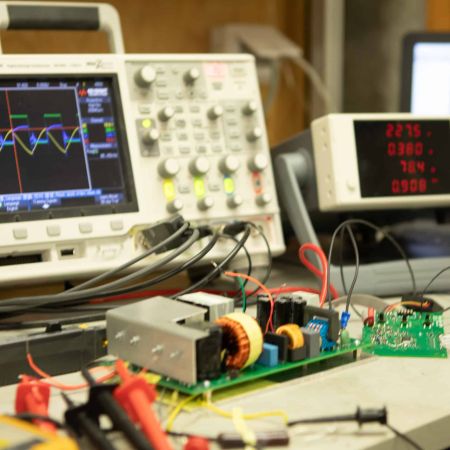

PFC for medical X-RAY machine

This interleaved PFC-power supply was developed already some years ago to our customer manufacturing X-ray machines.

Interleaved PFC involves the use of multiple interleaved converters to achieve power factor correction. These converters work together to process the input power, distribute the load, and collectively improve the power factor.

The term “interleaved” refers to the alternating or sequential operation of these multiple power stages.

Like in this case two-phase interleaved PFC, the two power stages operate in sequence, handling portions of the load in turn.

The interleaved converters are designed to share the current equally, ensuring that each power stage contributes its fair share to the overall load. Current sharing helps balance the load across the converters, improving efficiency and reliability.

Interleaved PFC reduces current and voltage ripple, leading to a smoother power delivery. This reduction in ripple helps lower stress on the components, improving the overall reliability and lifespan of the system.

By distributing the load across two converters and ensuring balanced operation, interleaved PFC typically improve the overall efficiency of the power factor correction system.

L7 drive battery backup module

L7 technology is based on single cell/parallel connected Li-Ion battery pack design with proprietary

technology. Cell voltage (typically 3.2 V – 3.6 V depending on cell chemistry) is raised to required

48V level by bi-directional converter unit.

This technology enables nearly unlimited scaling of battery capacity economically within L7 power

range without adding more complexity to electronics (such as traditional BMS based technologies)

L7Drive proprietary technology allows charging from unstable voltage and variable energy sources such as gensets, solar panels, windmills etc. Source: L7 drive datasheet

All power electronics for this unit is developed by Excello team.

Solution for LEV max. power 2kW

L7 Drive 250 and 2000 series power electronics units are versatile DC converters enabling robust and long-life parallel connected Li-ion battery pack to be used in multiple vehicle or DC-power applications with or without a motor control function. They can be supplied with an optional communication hardware that makes them fully connected with our real time cloud service for various remote control and monitoring functions for fleet operators or other use cases. Source L7 drive website

All power electronics for this project was developed by our team.